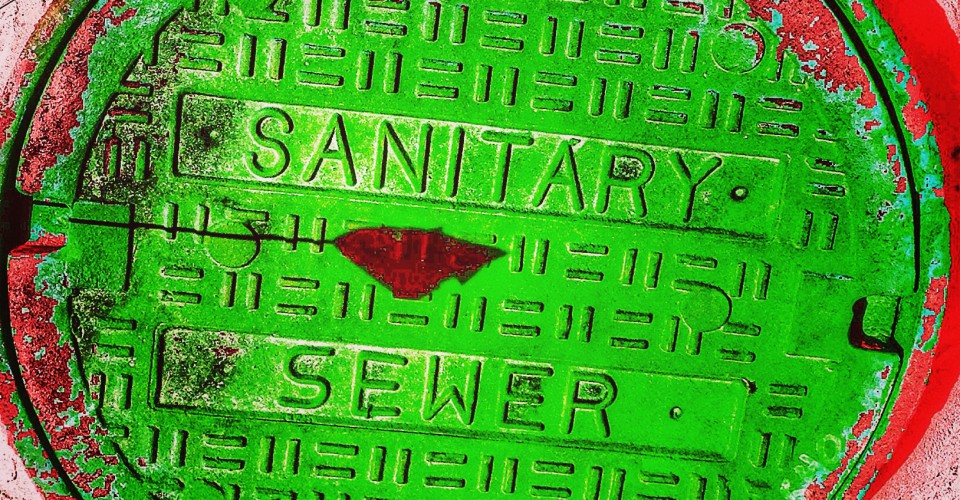

The EPA estimates that there are at least 40,000 sewer system overflows each year. In South Carolina, over the last 10 years, an average of almost 600 overflows are reported each year. Untreated sewage from these overflows can contaminate our waters, causing serious water quality problems. Sewage can also back…

Read More